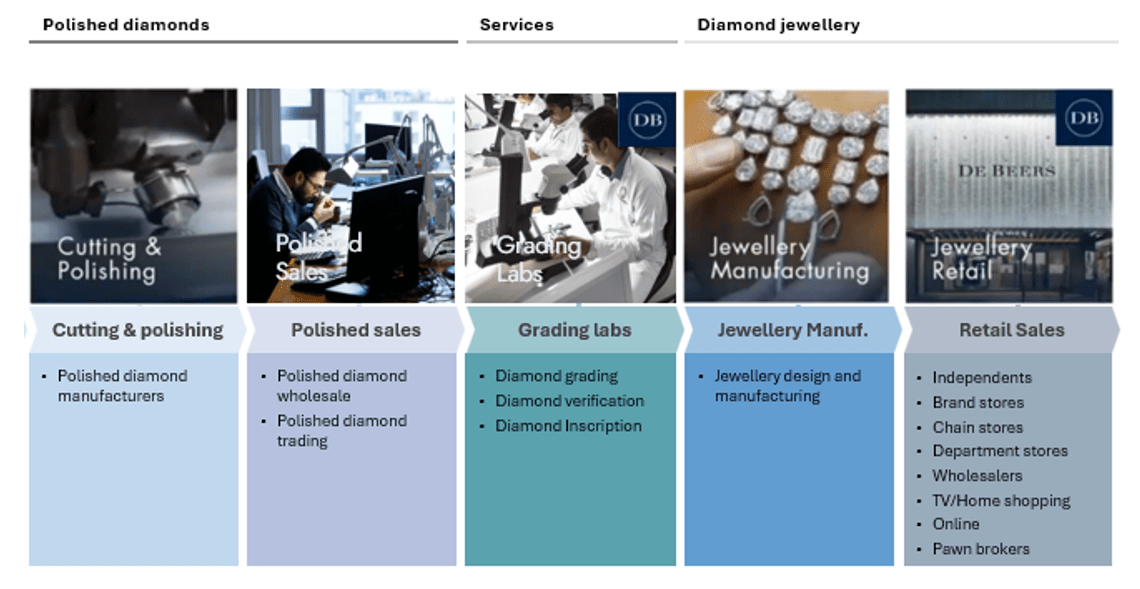

As synthetic diamonds become increasingly prevalent in the jewellery industry, the need to screen diamond parcels and finished pieces to verify their source has grown significantly. Given the diversity and scale of the diamond industry, screening requirements vary across different customer segments.

When deciding how to screen diamonds—and which device(s) to use—there are several key questions to consider.

Loose Diamonds vs. Mounted Jewellery

The first question is whether you need to screen loose stones or finished jewellery. Screening loose diamonds is often easier because the entire stone is accessible for testing. Once a diamond is set, parts of it may be hidden, which can limit what certain devices can analyse. Some instruments require full visibility of the diamond, while others only need access to a portion of the material.

Diamond Size and Volume

Next, consider the size of the diamonds. For melee stones, an automated screening process is highly beneficial as it speeds up throughput. Automated systems tend to be more expensive, so they are most cost-effective when screening large quantities. Larger diamonds, which carry higher value, can be screened individually—a process that is acceptable given their worth. These stones are typically submitted to a gemmological laboratory for a formal grading report.

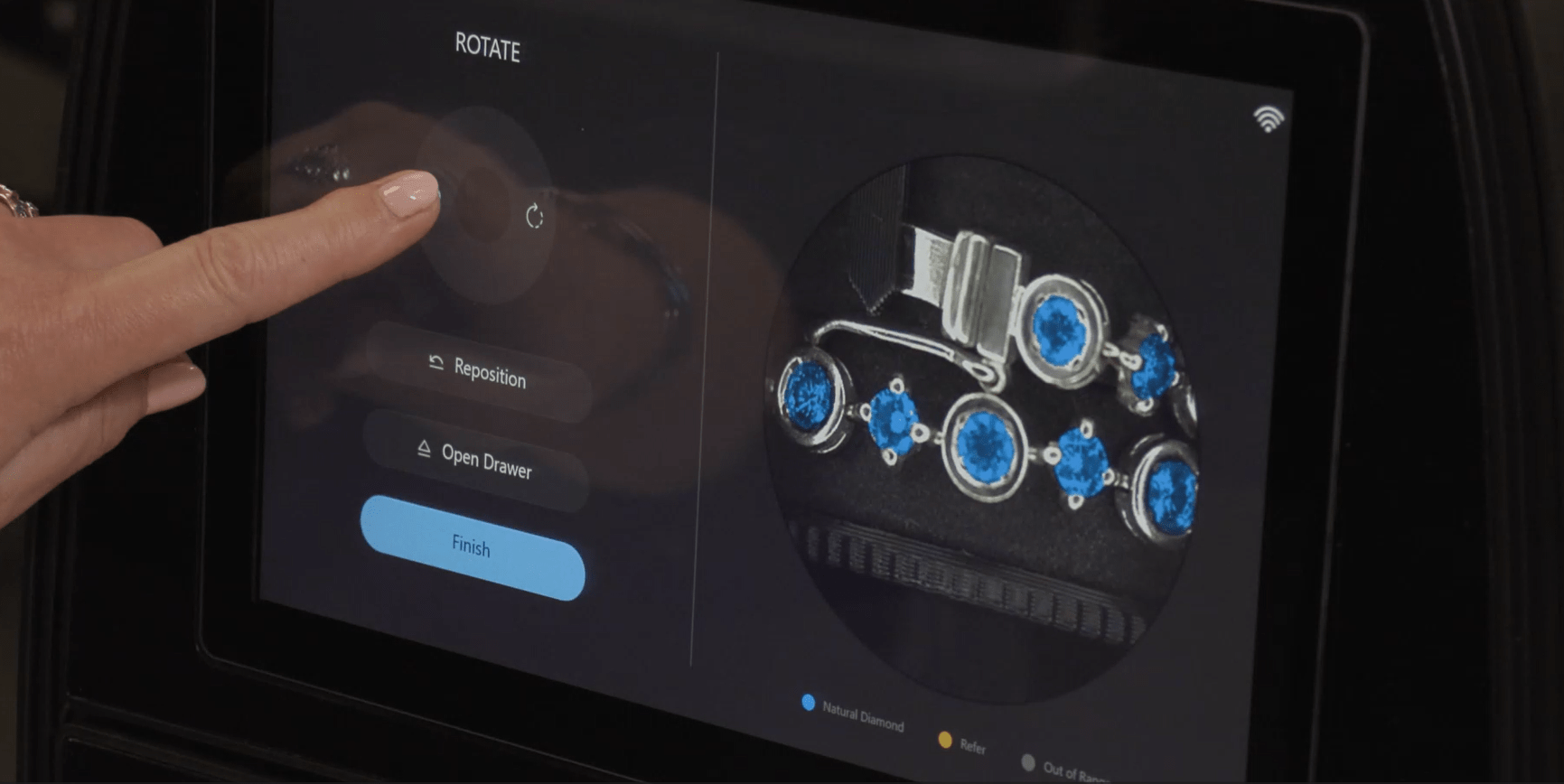

Screening Jewellery

Screening set jewellery presents unique challenges. Every diamond in the piece must be examined, and intricate designs can make this process difficult. In some cases, stones may need to be unmounted—a solution that is far from ideal. The objective is to select a device capable of testing most jewellery pieces without requiring disassembly.

Device Capabilities and Limitations

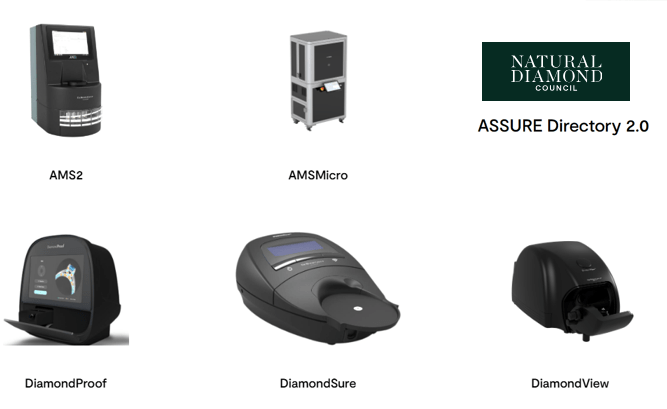

There are numerous screening devices on the market, so understanding what each can—and cannot—do is critical. Some instruments are limited by size, cut, or color. Most devices will identify natural versus synthetic origin but will not detect clarity or colour treatments.

Research and Independent Testing

It’s important to do your research. A good starting point—besides consulting this website or speaking with the De Beers verification team—is the Natural Diamond Council’s Assure Program. Assure Program: Diamond Verification Instrument Testing

This independent testing initiative provides comparative metrics and results. Manufacturers submit their instruments for evaluation using Assure’s standardised sample sets, which include natural diamonds, synthetics, and simulants. The results are then published on the Assure website for transparency.

When evaluating diamond screening devices, several performance metrics are critical:

Diamond Accuracy

The percentage of diamonds correctly identified as natural diamonds out of the total tested.

Ideal: 100%

Diamond Referral Rate

The percentage of diamonds flagged as “refer” for further testing.

Ideal: 0%

Diamond False Positive Rate

The percentage of synthetic diamonds or simulants incorrectly classified as natural diamonds.

Ideal: 0%

The Diamond False Positive Rate is the most important metric. For complete confidence, no instrument should ever classify a synthetic diamond as natural.

Another metric, shown in the full report but not on the summary fact sheet, is the Synthetic Diamond False Positive Rate—the percentage of natural diamonds incorrectly identified as synthetic. Whilst not as damaging, this is still not ideal, and this percentage figure is also worth considering when selecting a device.

De Beers Diamond Verification Instruments (DVIs)

All De Beers DVIs achieve 0% Diamond False Positive Rate and maintain low referral rates. This level of accuracy is possible thanks to ongoing diamond research that runs alongside instrument development, ensuring robust performance now and in the future.

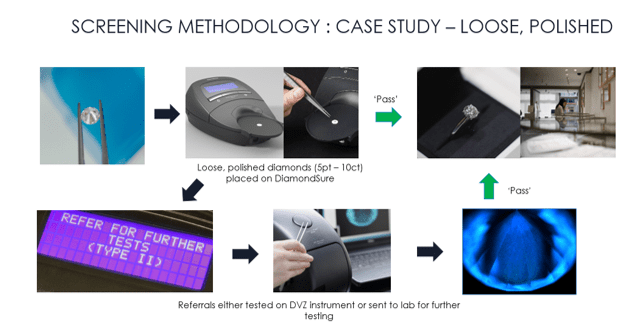

Devices such as DiamondSure, SynthDetect, and AMS2 can be combined with DiamondView for loose stones. A typical screening process might involve:

- Passing stones on a primary screening device (no further testing needed).

- Referring flagged stones to DiamondView for advanced analysis.

Alternatively, your workflow could start with in-house screening, followed by submission to a gemmological laboratory for any stones requiring further verification. While most uncertainties can be resolved internally, the unique characteristics of natural diamonds mean that some cases will always demand additional attention.

The De Beers team is always available to provide guidance on Diamond Verification Instruments (DVIs). Even if you already own one of our devices, we can assist with optimizing your screening processes and interpreting results.

Please contact the team at [email protected]